Determination of the carbon footprint of products and development of solutions for its optimization.

Krastsvetmet, Krasnoyarsk Non-Ferrous Metals Plant named after V.N. Gulidov, Krasnoyarsk.

1. Calculation of greenhouse gas emissions and reporting for a company (industrial enterprise). Scope 1, 2, 3.

- Development of a methodology for calculating emissions per organization;

- Site visit, collection of information on production and supply chain in order to identify GHG emissions;

- Automation of calculations of greenhouse gas emissions – development of a Calculator for calculating emissions per organization;

- Calculation of the carbon footprint of products for the purposes of international certification. Selection of the most appropriate documents (PCR) that define the principles and requirements for the preparation of an environmental product declaration (EPD), the definition of boundary conditions and a description of the technological process. Collection of quantitative data on the production process;

- Development of LCA life cycle model – calculation of emissions for products;

- EPD EU carbon footprint certification;

- Training on the training platform for the course “Calculation, optimization and compensation of greenhouse gas emissions according to the best international practices.”

2. Strategy for reducing greenhouse gas emissions.

- Calculation of the reduction of greenhouse gas emissions at an industrial enterprise for the production of nitric acid

- Compensation cost calculation on ETS

- Project description:

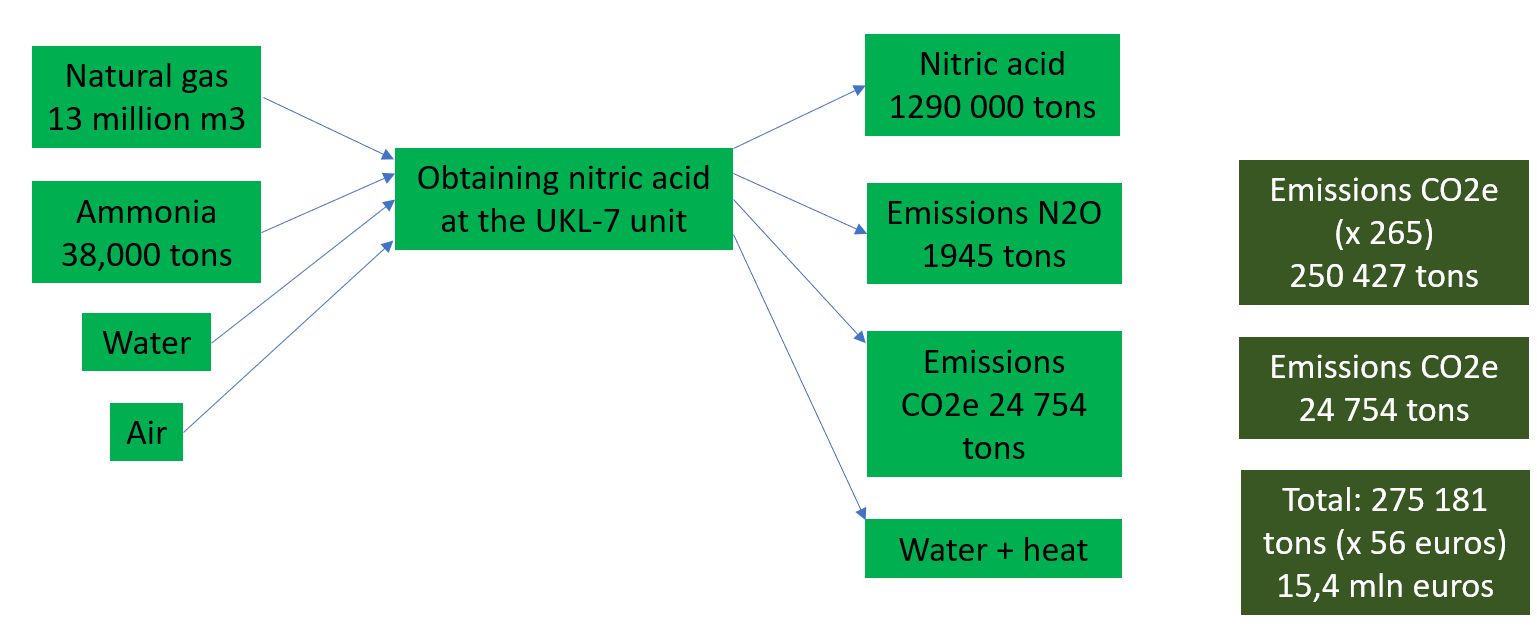

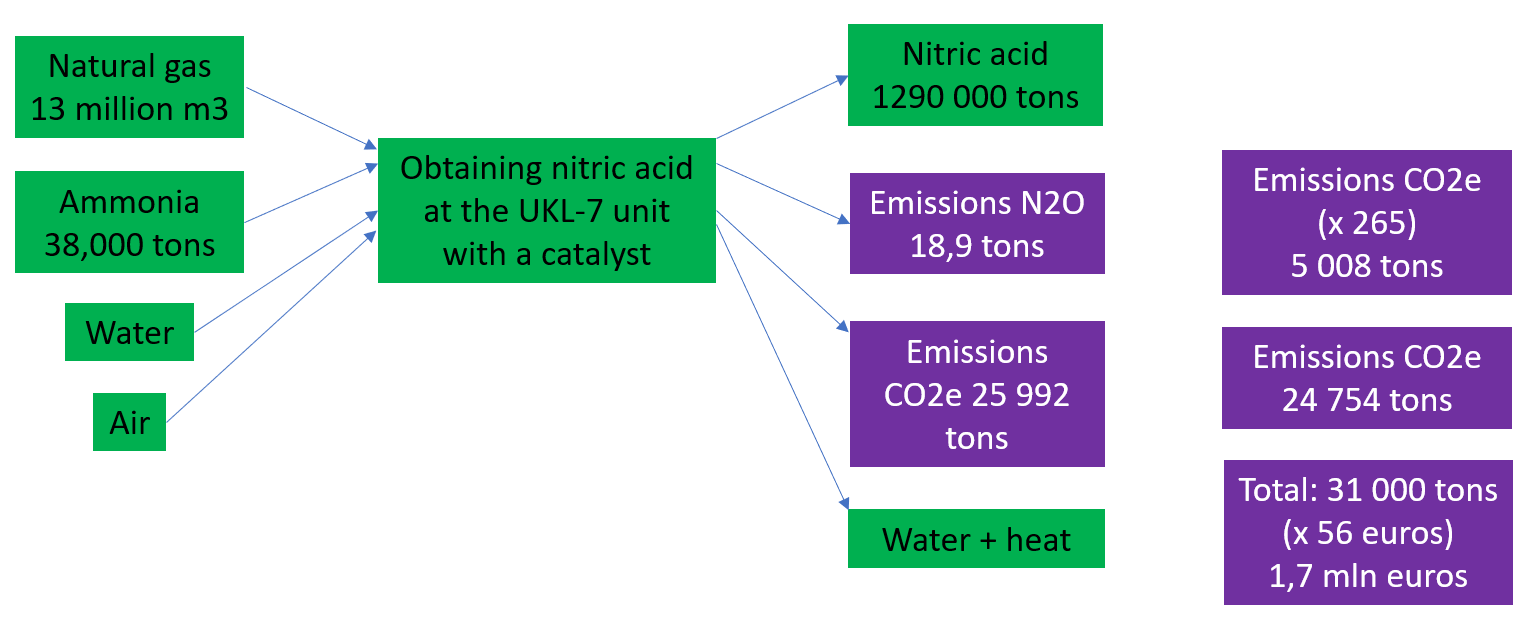

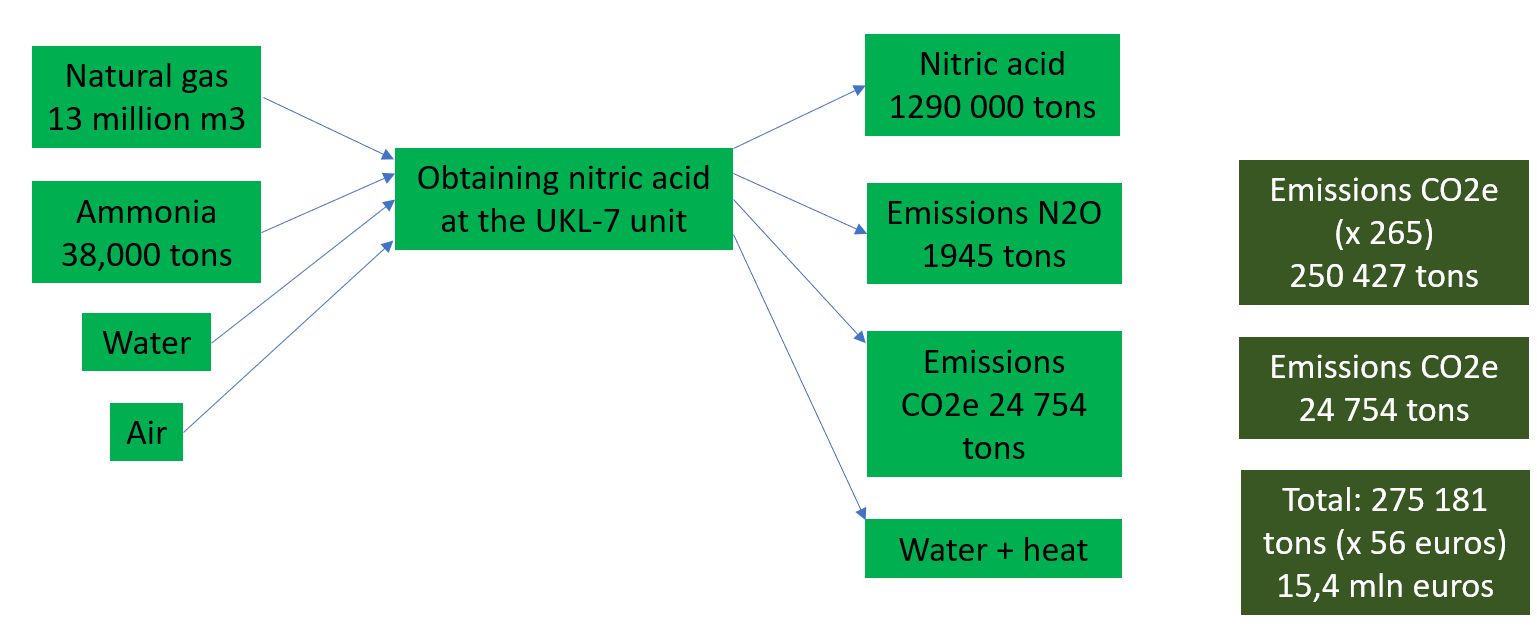

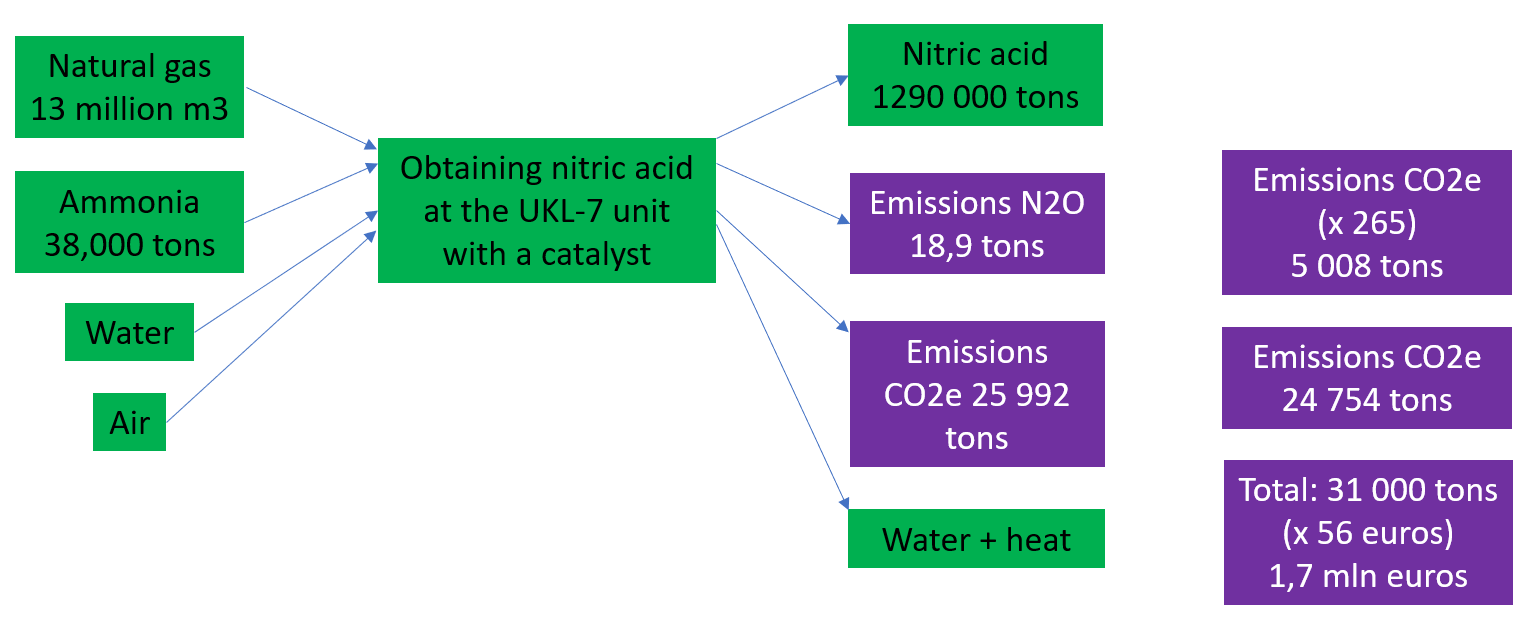

- HPBS calculated the reduction in CO2 emissions by adding a catalyst to the process for the production of nitric acid at the UKL-7 unit.

Our role:

- Strategic calculation of CO2 emission optimization

- Calculation of compensation cost on ETS

- Calculation of the unit cost of the product

Key achievements:

СО₂ emissions before installing the catalyst on the exhaust gases

СО₂ emissions after installing the catalyst on the exhaust gases

Comparison of options

|

Without catalyst

The cost of compensation on ETS is 15.4 million euros

or $120 per ton of acid |

Without catalyst

The cost of compensation on ETS is 15.4 million euros

or $120 per ton of acid

with catalyst

The cost of compensation on ETS is 1.7 million euros

or $13.5 per ton of acid

– N20 reduction by 98%

– 5% CO2 increase |

Links:

Calculation of the Carbon Footprint

https://hpb-s.com/en/services/epd-declarations-and-lca-product-life-cycle-analysis/

ESG for the bank. ESG reporting.

Сourse on calculating greenhouse gas emissions